Power Management ICs Simplify Integration of Supercapacitors in Energy Microharvesting Designs

Contributed By Electronic Products

2012-09-19

Energy-microharvesting applications such as wireless sensor nodes require periodic bursts of power well beyond that available in steady state from most ambient sources. In this respect, supercapacitors offer performance characteristics that are well suited for energy-harvesting environments. By combining supercapacitors with appropriate power and charge management circuitry, and using specialized devices from manufacturers including Linear Technology, Maxim Integrated, and Texas Instruments, engineers can exploit microharvesting techniques in applications with demanding peak power requirements.

Electrochemical double-layer capacitors (EDLC), or supercapacitors, are capable of discharging tens or even hundreds of milliamperes of current over the course of a few seconds (see the TechZone article "Supercapacitors Meet Unique Demands of Energy-Harvesting Applications"). For wireless sensor node applications, for example, this power output is well within the peak demand envelope of bursts of wireless communications. The efficient charge and discharge cycles of supercapacitors make them a good fit in burst-type applications such as wireless sensor nodes.

Similarly, their efficient charge/discharge characteristics make them well suited to specialized demands of microharvesting applications that must periodically "cold boot" after an extended absence of ambient energy has depleted all onboard charge storage devices. Here, the full application circuitry is reenergized sequentially after microharvesting circuitry first charges a bootstrap supercapacitor used to power subsequent stages of the bootstrap process.

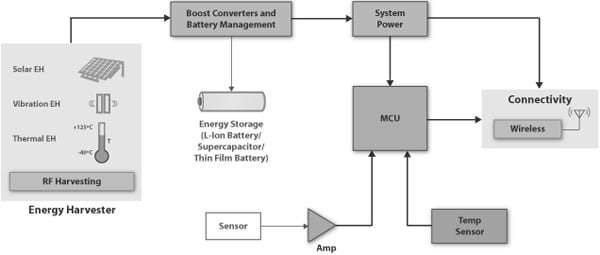

A typical microharvesting application uses supercapacitors as the sole storage device or as supplemental storage for peak or cold boot requirements (Figure 1). For load management, a DC/DC converter is required to maintain a stable supply voltage to the load because the voltage output of a supercapacitor is linearly proportional to the charge on the supercap. Engineers will typically use a buck-boost converter with low dropout to extract maximum power from the supercap even as charge levels drop under load.

Figure 1: In a typical microharvesting application, storage devices such as thin-film batteries typically provide a consistent source of power. Supercapacitors augment these designs with a ready source of energy for peak power demands. (Courtesy of Texas Instruments.)

In the charging stage, engineers need to reconsider traditional methods. For example, a diode used to prevent reverse current in solar applications would raise the supercap charging threshold by the amount of the diode drop. Similarly, the use of a voltage regulator might eliminate the diode drop and provide a lower charging threshold, but introduce problems as the supercapacitor nears depletion, when it would appear as a short circuit. As a result, the regulator would reduce current to correspondingly low levels — and dramatically increase charge time for the supercap. These factors become even more complex in systems using multiple supercapacitors, where charge balancing is required to ensure reliable charging. At the same time, these seemingly simple approaches to charge management actually complicate maximum power point tracking (MPPT) methods needed to maintain the solar cell, piezoelectric or other energy-source transducer at the dynamically changing I-V point corresponding to maximum power output from the transducer.

Available devices

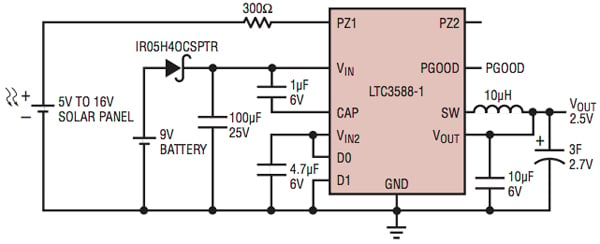

Engineers can choose from a variety of devices designed specifically to manage the unique requirements of supercapacitor charge management in microharvesting applications. For example, Linear Technology offers its LTC3588 as a complete energy-harvesting power supply that provides features for charging large storage devices such as supercapacitors (Figure 2). Among other features, the LTC3588 combines a buck converter with a full-wave bridge rectifier needed for AC power sources such as piezoelectric transducers but can harvest pure DC sources as well. The device features an undervoltage lockout (UVLO) mode that allows charge to accumulate on the storage capacitor until the buck converter needs to turn on to serve the load.

Figure 2: Engineers can implement a complete supercapacitor-based power supply powered by ambient solar energy using the Linear LTC3588 with only a few additional components. (Courtesy of Linear Technology.)

In operation, the LTC3588 turns on its buck converter when Vin rises above the UVLO rising threshold. The buck converter then transfers charge from the input capacitor to the output capacitor. Conversely, when the input capacitor voltage falls below the UVLO falling threshold, the buck converter is disabled. With the buck converter disabled in UVLO, the LTC3588 consumes about 450 nA, permitting the LTC3588 to support energy harvesting from very-low-power sources. With this approach, a design can store harvested energy on the input capacitor or output capacitor. Although current is limited to the buck converter's supply capabilities when drawing on the input capacitor, engineers can use larger output capacitors to support larger currents.

The Texas Instruments BQ25504 IC features a boost converter designed to ensure energy harvesting from energy input sources as low as 80 mV. Using pulse-frequency modulation (PFM), the BQ25504 regulates input voltage VIN_DC close to the desired reference voltage, which is set by sampling a preset ratio of the open-circuit voltage of the energy harvester once every 16 s. Engineers can set this ratio with resistors to an appropriate value — typically 0.8 for solar harvesters. Because it turns out that the maximum power point of solar cells is about 80 percent of their open-circuit voltage, this mechanism provides a simple but accurate form of MPPT.

In operation, the device holds the sampled reference voltage on VREF_SAMP. When the input voltage exceeds VREF_SAMP, the device maintains input voltage regulation (and the maximum power point) by transferring charge from the input to the load through its VSTOR pin. Engineers can connect supercapacitors to the device's VBAT pin and rely on the BQ25504's internal circuitry to optimize charging of the supercapacitor.

The Maxim MAX17710 similarly relies on an internal boost converter to allow supercapacitor charging from input sources as low as 0.75 V. An LDO linear regulator independently manages output voltage to the load in selectable low-power modes designed to maximize energy storage on the supercapacitor or other storage device. In operation, the MAX17710 passes current directly to the supercapacitor (at pin BATT) — without any further intervention from the device — whenever the input source voltage (at pin CHG) exceeds the voltage on BATT. When CHG voltage exceeds the CHG enable threshold (VCE), the device limits charging voltage to prevent overcharging and also enables the LDO to begin powering the application load.

Summary

Supercapacitors can offer an ideal solution for microharvesting applications characterized by long periods of inactivity interrupted by bursts of activity. For these applications, supercapacitors can typically easily meet demands for peak power that lie well above the steady-stage power available from the ambient energy source. By drawing on specialized power management devices, engineers can readily incorporate supercapacitors in microharvesting circuits.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.